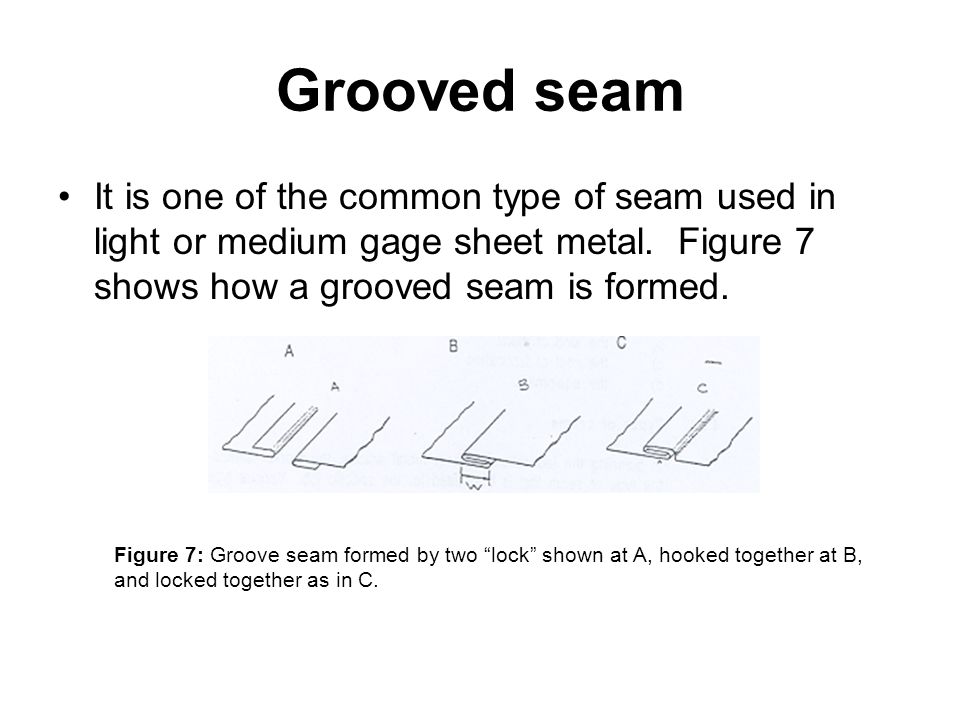

Grooved seam are a type of self locking joint used commonly in the fabrication of cylindrical and conical objects.

Tools for making a grooved joint seem in sheet metal.

The grooved seam joint fig.

4 4 out of 5 stars 138.

Rk edge treatment of sheet metal terminology.

Manual sheet metal grooving tool don t forget to subscribe.

Sk rk use and care of tools machinery and equipment especially the box and pan folders.

Free shipping by amazon.

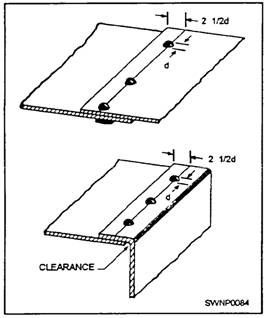

Up to 4 times the material thickness may also need to be added for thicker.

Rk safety housekeeping maintain due care in handling and forming sheet metal.

The lock seam which has an additional fold and is often used for corner seams is a type of grooved seam.

Get it as soon as fri sep 18.

Crescent wiss 24 folding tool wf24.

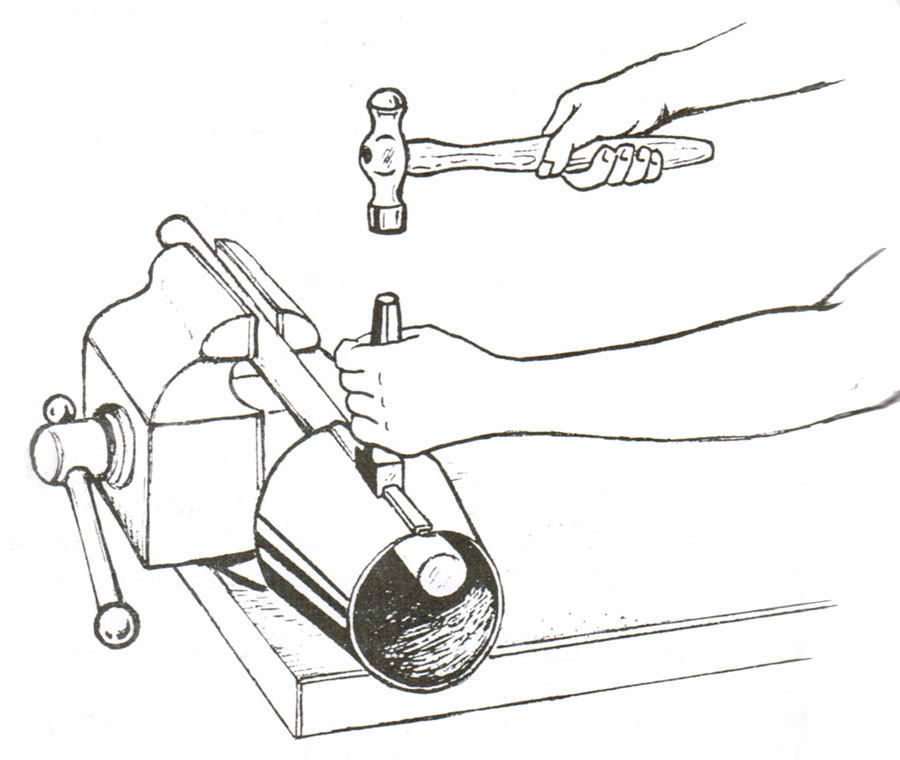

Manual grooved seams are pounded with a mallet to finish with no soldering required.

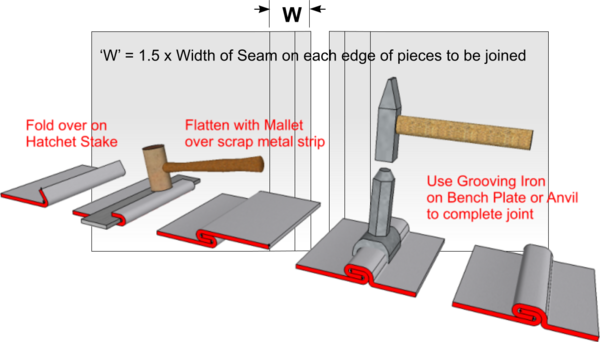

The extra material allowance for a grooved seam is 3 times the width w of the seam one half of this amount being added to each edge note.

2 57 is one of the most widely used methods for joining light and medium gauge sheet metal.

When making a grooved seam on a cylinder you fit the piece over a stake and lock it with the hand groover fig.

Calculate groove allowance and form grooved joint as per drawing key learning points.

The grooved seam is commonly used to construct objects made of light sheet metal such as air ducts.

It consists of two folded edges that are locked together with a hand groover fig.